x

Substation Structures

200.0 INR/Kilograms

Product Details:

- Product Type Substation Structure

- Material Mild Steel / High Tensile Steel

- Welding Standard IS 9595 / AWS D1.1

- Capacity Customized as per project

- Application Electrical Substations

- Galvanization Standard IS 2629 / ASTM A123

- Out Coating Hot Dip Galvanized

- Click to View more

X

Substation Structures Price And Quantity

- 10000 Kilograms

- 200.0 INR/Kilograms

Substation Structures Product Specifications

- IS 2629 / ASTM A123

- Angular / Tubular / Custom

- Substation Structure

- Modular / Tailor-made

- Hot Dip Galvanized

- IS 9595 / AWS D1.1

- 4 mm to 20 mm

- Corrosion Resistant

- Silver Grey

- IEC / IS / ASTM

- Mild Steel / High Tensile Steel

- Customized as per project

- Up to 30 meters

- Electrical Substations

- Up to 765 kV

Substation Structures Trade Information

- 1 Kilograms Per Week

- 1 Week

Product Description

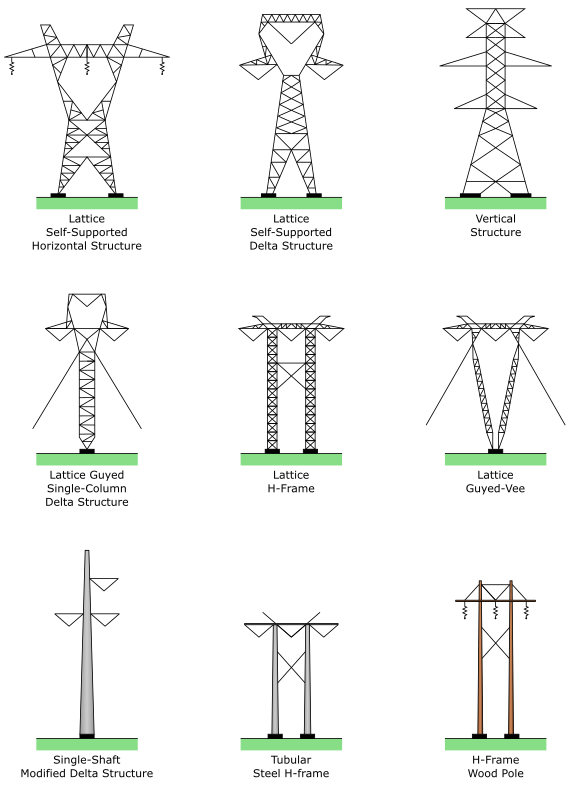

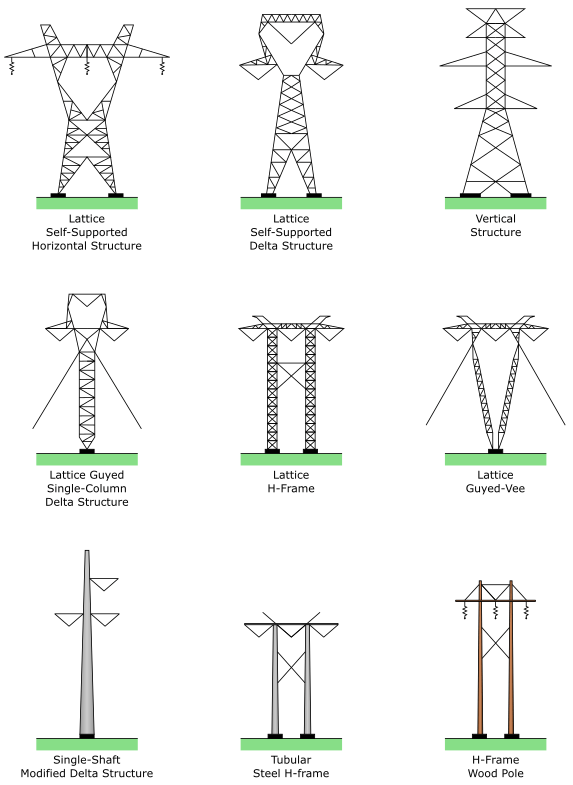

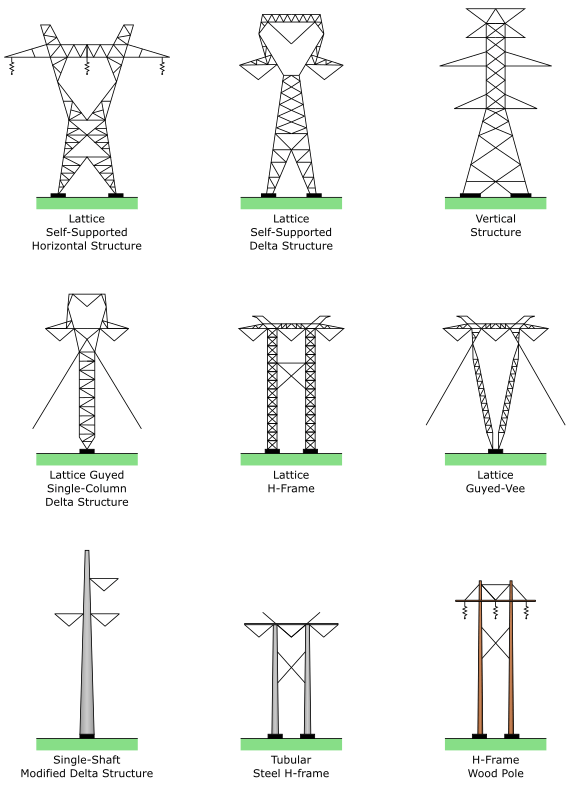

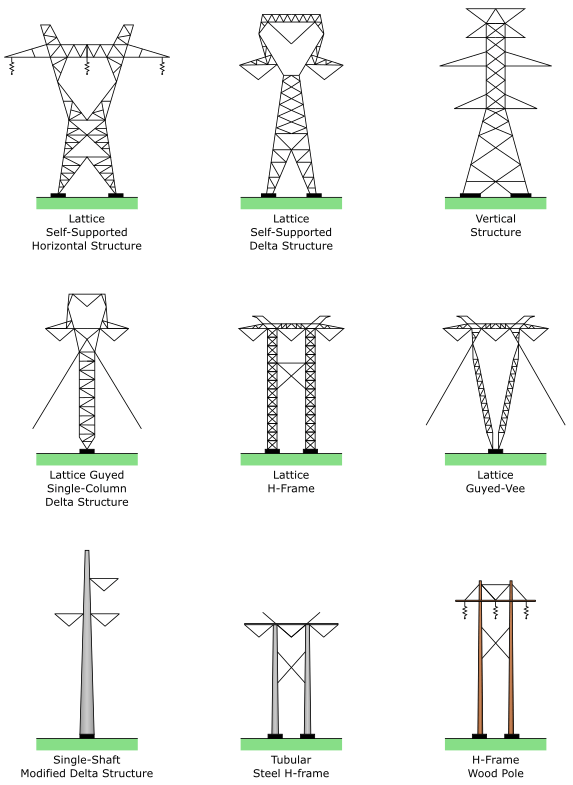

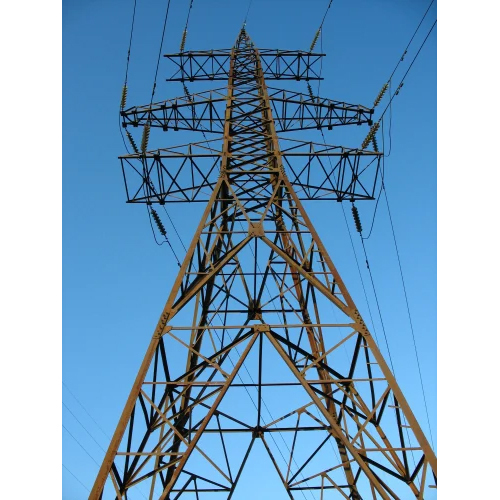

Our transmission towers are engineered to carry high-voltage power lines safely and efficiently across long distances. Designed for strength, stability, and durability, these towers withstand harsh weather conditions while ensuring uninterrupted power transmission. Available in various typesincluding lattice towers, monopoles, and guyed towersour solutions meet international standards and are ideal for power distribution, industrial, and utility applications. Reliability, safety, and long-term performance are at the core of every structure we deliver.Superior Structural Integrity

Crafted from high tensile and mild steel, these substation structures feature angular, tubular, or custom profiles for enhanced strength. Bolted and welded connections adhere to IS and AWS standards, ensuring a solid, resilient framework tailored to demanding electrical environments.

Reliable Corrosion Protection

Each section receives a uniform hot-dip galvanized finish compliant with IS 2629 and ASTM A123, delivering exceptional corrosion resistance. This treatment extends the lifespan of the structure and keeps maintenance requirements minimal, even in challenging weather conditions.

Custom Modular Design

Modular configurations allow for tailored design, accommodating project-specific heights (up to 30 meters), capacities, and voltages up to 765 kV. Knockdown packaging and prefabrication streamline transport and onsite assembly, supporting fast deployment for substations across India.

FAQs of Substation Structures:

Q: How are the substation structures installed on-site?

A: Substation structures arrive in prefabricated sections and knockdown form for easy transport. Installation can be completed on-site or off-site using concrete or grouted foundations, with assembly guided by modular design for rapid, efficient deployment.Q: What benefits do the hot-dip galvanized surfaces offer?

A: Hot-dip galvanization, meeting IS 2629 and ASTM A123 standards, significantly enhances corrosion resistance. This process provides a uniform finish that protects against harsh environments, reduces maintenance, and ensures a long service life of over 25 years.Q: Where can these substation structures be used?

A: These structures are suitable for electrical substations across various terrains in India, designed to withstand wind loads up to 180 km/h and seismic forces as required by IS 1893. They support versatile applications and customizable configurations.Q: What is the process for customizing a structure to project requirements?

A: Customization involves tailoring the height (up to 30 meters), load capacity, shape, and voltage parameters as per project needs. The manufacturer or supplier works directly with clients to design and fabricate structures that align with IEC, IS, or ASTM standards.Q: When is maintenance required for these substation structures?

A: Thanks to corrosion-resistant surface treatment and precision engineering, these structures require minimal maintenance over their lifespan. Regular inspection is recommended, but the galvanized coating and robust build minimize the need for frequent servicing.Q: What accessories are provided with the substation structures?

A: Standard accessories include earthing lugs, ladders, fasteners, and other essential fittings to support safe operation and streamlined installation. All components are compatible with the modular design for convenient assembly and use.Q: How does the structure ensure safety against natural disasters?

A: Each structure is engineered for seismic resistance according to IS 1893 standards and is capable of withstanding wind loads up to 180 km/h. Foundation types and materials are selected to maximize stability and safety under extreme environmental conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email